Thermal and Mechanical Behavior of Wood Plastic Composites by Addition of Graphene Nanoplatelets

Abstract

:1. Introduction

2. Materials and Experiment

2.1. Materials Collection

2.2. Sample Preparation

2.3. Sample Characterization

2.3.1. Morphology Analysis

2.3.2. Thermal Properties

3.2. Thermal Properties

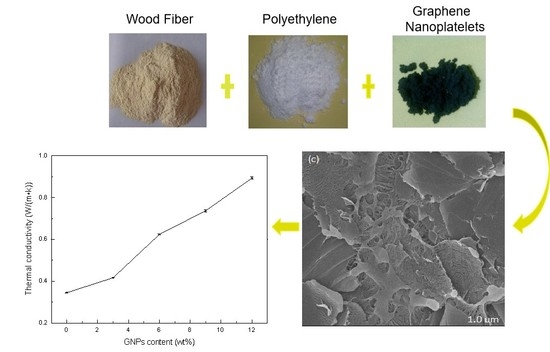

3.2.1. Effect of GNPs Content on the Thermal Conductivity

3.2.2. Effect of Temperature on the Thermal Conductivity

3.2.3. Thermogravimetric Analysis (TG)

3.2.4. The Limiting Oxygen Index (LOI) Test

3.2.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Q.W.; Wang, W.H.; Song, Y.M. Wood-Plastic Composites and Products; Chemical Industry Press: Bei**g, China, 2007. [Google Scholar]

- Fang, H.M.; Bai, S.L.; Wong, P. Microstructure engineering of graphene towards highly thermal conductive composites. Compos. Part A 2018, 112, 216–238. [Google Scholar] [CrossRef]

- Verdejo, R.; Bernal, M.M.; Romasanta, L.J. Graphene filled polymer nanocomposites. J. Mater. Chem. 2011, 21, 3301–3310. [Google Scholar] [CrossRef]

- Birm, J.K.; Fei, Y.; Han, G.; Wang, Q.W.; Wu, Q.L. Mechanical and physical properties of core–shell structured wood plastic composites: Effect of shells with hybrid mineral and wood fillers. Compos. Part B 2013, 45, 1040–1048. [Google Scholar]

- Teng, C.C.; Ma, C.C. Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 2011, 49, 5107–5111. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Grybczuk, M.; Chmielewski, M. Thermal conductivity of metal-graphene composites. Mater. Des. 2016, 99, 163–173. [Google Scholar] [CrossRef]

- Huang, C.; Qian, X.; Yang, R. Thermal conductivity of polymers and polymer nanocomposites. Mater. Sci. Eng. R 2018, 132, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Chu, K.; Wang, X.; Li, Y. Thermal properties of graphene/metal composites with aligned graphene. Mater. Des. 2018, 140, 85–94. [Google Scholar] [CrossRef]

- Khan, M.F.S.; Alexander, A.B. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar]

- Zhou, T.; Wang, X.; Cheng, P.; Wang, T.; **ong, D.; Wang, X. Improving the thermal conductivity of epoxy resin by the addition of a mixture of graphite nanoplatelets and silicon carbide microparticles. Express Polym. Lett. 2013, 7, 585–594. [Google Scholar] [CrossRef]

- **ang, J.; Drzal, L.T. Thermal conductivity of exfoliated graphite nanoplatelet paper. Carbon 2011, 49, 773–778. [Google Scholar] [CrossRef]

- Shahil, K.M.F.; Balandin, A.A. Thermal properties of graphene and multilayer graphene: Applications in thermal interface materials. Solid State Commun. 2012, 152, 1331–1340. [Google Scholar] [CrossRef]

- Tang, B.; Hu, G.; Gao, H. Application of graphene as filler to improve thermal transport property of epoxy resin for thermal interface materials. Int. J. Heat Mass Transf. 2015, 85, 420–429. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, X.; Hao, J.; Wang, Q. Heat transfer and mechanical properties of wood-plastic composites filled with flake graphite. Therm. Acta 2018, 664, 26–31. [Google Scholar] [CrossRef]

- Malekpour, H.; Chang, K.H.; Chen, J.C. Thermal conductivity of graphene laminate. Nano Lett. 2014, 14, 5155–5161. [Google Scholar] [CrossRef]

- Gu, J.; Du, J.; Dang, J.; Geng, W.; Hu, S.; Zhang, Q. Thermal conductivities, mechanical and thermal properties of graphite nanoplatelets/polyphenylene sulfide composites. RSC Adv. 2014, 4, 22101–22105. [Google Scholar] [CrossRef]

- Sayanthan, R.; Wang, X.; Jay, S.; John, W. Heat transfer performance enhancement of paraffin/expanded perlite phase change composites with graphene nano-platelets. Energy Procedia 2017, 105, 4866–4871. [Google Scholar]

- Dilek, K.; Ismail, H.T.; Turhan, C. Thermal conductivity of particle filled polyethylene composite materials. Compos. Sci. Technol. 2003, 63, 113–117. [Google Scholar]

- Guo, C.; Zhou, L.; Lv, J. Effects of Expandable Graphite and Modified Ammonium Polyphosphate on the Flame-Retardant and Mechanical Properties of Wood Flour-Polypropylene Composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar] [CrossRef]

- Bin, Y.; Shi, Y.; Yuan, B.; Qiu, S.; **ng, W.; Hu, W.; Song, L.; Loc, S.; Hu, Y. Enhanced thermal and flame retardant properties of flame-retardant-wrapped graphene/epoxy resin nanocomposites. J. Mater. Chem. A 2015, 3, 8034–8044. [Google Scholar]

- Robertson, D.H.; Brenner, D.W.; Mintmire, J.W. Energetics of nanoscale graphitic tubules. Phys. Rev. B 1992, 45, 12592. [Google Scholar] [CrossRef]

- Brenner, D.W.; Shenderova, O.A.; Harrison, J.A. A second-generation reactive empirical bond order (REBO) potential energy expression for hydrocarbons. J. Phys. Condens. Matter 2002, 14, 783. [Google Scholar] [CrossRef]

- Yavari, F.; Fard, H.R.; Pashayi, K. Enhanced thermal conductivity in a nanostructured phase change composite due to low concentration graphene additives. J. Phys. Chem. C 2011, 115, 8753–8758. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, X.; Hao, J. Thermal and mechanical properties of wood-plastic composites filled with multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2018, 135, 46308. [Google Scholar] [CrossRef]

- Rishi, A.M.; Kandlikar, S.G.; Gupta, A. Improved wettability of graphene nanoplatelets (GNP)/copper porous coatings for dramatic improvements in pool boiling heat transfer. Int. J. Heat Mass Transf. 2019, 132, 462–472. [Google Scholar] [CrossRef]

| Sample | WF (wt %) | PE (wt %) | MAPE (wt %) | GNPs (wt %) |

|---|---|---|---|---|

| Control | 40 ± 1.5 | 57 ± 1.5 | 3 ± 0.1 | 0 |

| WPC3 | 40 ± 2.0 | 54 ± 1.5 | 3 ± 0.2 | 3 |

| WPC6 | 40 ± 1.4 | 51 ± 1.2 | 3 ± 0.1 | 6 |

| WPC9 | 40 ± 1.7 | 48 ± 1.2 | 3 ± 0.1 | 9 |

| WPC12 | 40 ± 2.0 | 45 ± 1.0 | 3 ± 0.2 | 12 |

| Sample | T5 (°C) | T10 (°C) | T50 (°C) | Tmax (°C) |

|---|---|---|---|---|

| Control | 296.85 | 329.00 | 482.53 | 373.53/496.33 |

| WPC6 | 299.32 | 332.35 | 486.44 | 373.79/498.18 |

| WPC12 | 299.56 | 339.12 | 494.07 | 374.14/502.14 |

| WPC Type | Flexural Strength (MPa) | Flexural Modulus (GPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| Control | 45.89 ± 0.62 | 1.96 ± 0.02 | 22.52 ± 0.41 | 1.44 ± 0.03 | 9.71 ± 0.56 |

| WPC3 | 41.59 ± 0.65 | 2.32 ± 0.02 | 21.05 ± 0.47 | 1.45 ± 0.04 | 8.75 ± 0.43 |

| WPC6 | 42.43 ± 0.71 | 2.50 ± 0.03 | 20.53 ± 0.42 | 1.56 ± 0.06 | 8.42 ± 0.46 |

| WPC9 | 46.51 ± 0.57 | 2.89 ± 0.05 | 20.12 ± 0.32 | 1.65 ± 0.05 | 8.40 ± 0.51 |

| WPC12 | 47.51 ± 0.35 | 2.90 ± 0.04 | 20.10 ± 0.41 | 1.67 ± 0.04 | 8.32 ± 0.23 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, J.; Wang, R. Thermal and Mechanical Behavior of Wood Plastic Composites by Addition of Graphene Nanoplatelets. Polymers 2019, 11, 1365. https://doi.org/10.3390/polym11081365

Zhang X, Zhang J, Wang R. Thermal and Mechanical Behavior of Wood Plastic Composites by Addition of Graphene Nanoplatelets. Polymers. 2019; 11(8):1365. https://doi.org/10.3390/polym11081365

Chicago/Turabian StyleZhang, **ngli, **glan Zhang, and Ruihong Wang. 2019. "Thermal and Mechanical Behavior of Wood Plastic Composites by Addition of Graphene Nanoplatelets" Polymers 11, no. 8: 1365. https://doi.org/10.3390/polym11081365